Menu

Click through our price calculator and get a quote for prototypes or serial production in plastic, light metal or EPS/EPP.

From idea to finished tool in two weeks.

''They have been incredibly fast and creative partners''

Rasmus Gruusgaard, Senior Consultant and the Danish Plastics Federation

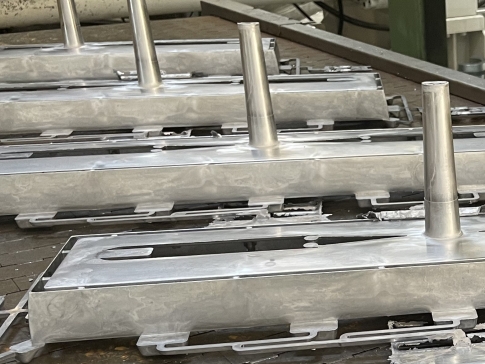

Before production started, we assisted NOAQ Flood Protection AB with material selection, DFM and flow analysis. We then manufactured the large moulding tool at our in-house tool factory.

We are expanding our plastic production capacity with another injection moulding machine.

After choosing Idé-Pro, Louis Poulsen has received high-pressure die-cast items in the exact quality and speed they required.

''We reach the desired parts faster''

Bjarne Hechmann, Senior Manager Product Engineering, Louis Poulsen

Idé-Pro, in collaboration with the horticulture company Wellfarmed, has developed technical EPP items for an innovative system, where vegetables are grown without soil, within a few square meters, and with extremely low water consumption.

''They helped us move from idea to product in record time.''

Sune Rasmussen, Director, Wellfarmed

We understand that efficiency is paramount to our customers, which is why we pay close attention to part design and construction. Designing parts can be complex and to ensure an efficient production process, it's important that a part is designed correctly and accurately.

That's why we carefully review whether your part is ready for production when it's fully designed. Is the grinding angle optimal? Is the material thickness appropriate? Here we use DFM analyses, among other things. Our standard practice always includes extensive quality control - also during production to ensure that the product meets the standards.

At Idé-Pro, we have high ambitions for sustainability and take active responsibility for our role in the world. We want to be frontrunners in the responsible production of prototypes in plastic, light metal and EPP/EPS and want to set a good example to our customers, suppliers, partners and competitors.

We do this through a high level of energy management and optimisation, as well as post-industry recycling and post-consumer recycling using our in-house extrusion and compounding facilities. We also take social responsibility and want to make Idé-Pro a workplace with room for everyone, where our employees are happy to come to work.

With in-house product development, tool making, plastic, light metal and EPS/EPP moulding, metrology and assembly, we can help with all necessary processes. You are guaranteed a short lead time, high flexibility and competitive prices. Idé-Pro is your partner from idea to prototype, product and production.